Our technology

Since 1995 – Ultrasonic soldering with high corrosion protection, as well as without flux and metallisation of metals, light metals, ceramics and glasses without flux with heavy metal-free solders at soldering temperatures from 150 oC to 480 oC in accordance with RoHS guidelines.

Environmentally friendly solution

- No pollution of the environment and humans due to flux-free processes and the use of lead-free solders

- No subsequent cleaning of components from flux residues necessary

- Saving and conserving scarce resources

- Repair of components to increase service life

Perfect solderings

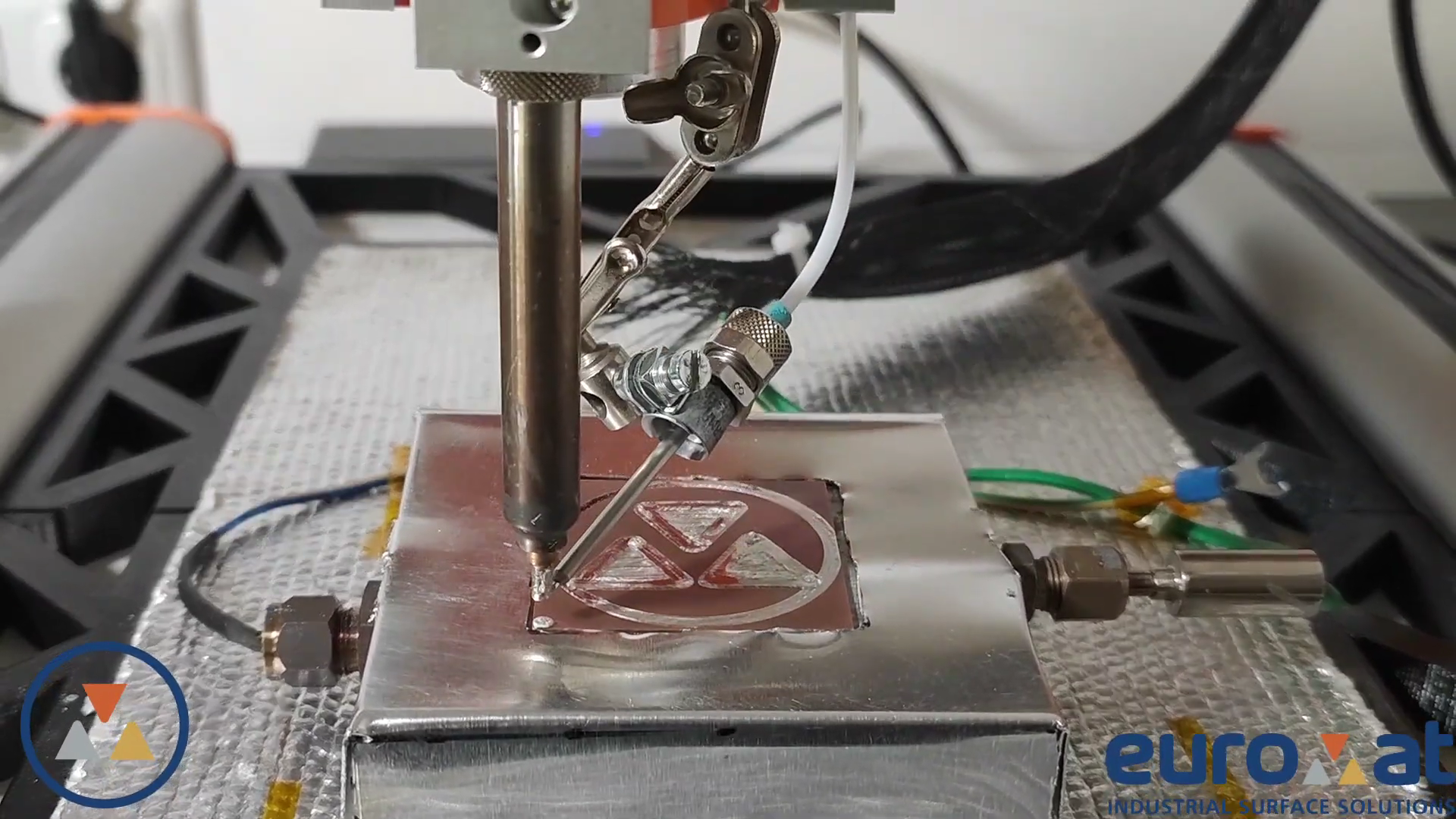

- Ultrasonic energy penetrates into the surface areas and provides metallurgical bonds with high strength

- A wide range of metals, light metals, ceramics, composites and glasses can be soldered and metallised

- Dense solder layers with corrosion-free solder joints due to flux-free process

- Very good thermal and electrical properties

Economical process with high cost saving potential

- Cost saving due to avoidance of cleaning and disposal costs caused by fluxes

- Metallisation costs, e.g. for Al materials, are eliminated

- Cost savings through material substitution, e.g. Cu by Al

- Simple process and automatable

Enables new application developments and product features

- Successful brazing of new materials in the fields of metals, light metals, ceramics, composites and glasses allow new product developments and increases in component efficiency

- Numerous customers use ultrasonic soldering technology in the fields of solar, battery technology, electronics, electrical engineering, motor construction, transformers, vacuum technology, filter technology, semiconductors, heat exchangers, ceramic applications, sensor technology and much more.